Integration of inspection, analysis and action, real-time perception of the health status of transmission lines

Integration of inspection, analysis and action, real-time perception of the health status of transmission lines

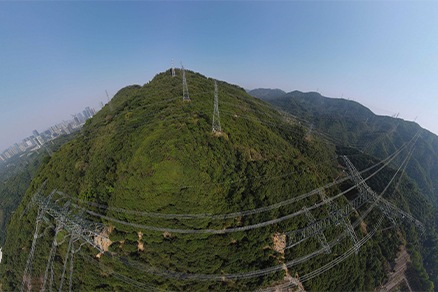

Carry out intelligent inspection of overhead lines through utilization of fixed-wing UAVs, take high-definition aerial photos of line passages, surrounding environments, intersections along lines, construction operations, etc. This process is especially important for key power supply lines, old lines, identifying defects and external lines. Lines that break through high-risk areas can be supported via a normal inspection schedule by drones, easily identifying environmental health of transmission line channels in real time, and effectively promote the digital and intelligent transformation of power grid inspections.

Continuous increase of inspection tasks leads to manpower shortage, inspection paths easily disrupted and changed.

3D waypoint planning is complex and labor-intensive, a single inspection takes a long time, often leading to a large backlog of tasks.

Abnormal situations cannot be fed back in real time, situation descriptions lack standards, and ineffective communication leads to ultimately slow responses to repairing defects.

Weather and environments are naturally complex, fight platforms need to be able to maintain stable and efficient operations in various adverse environments.

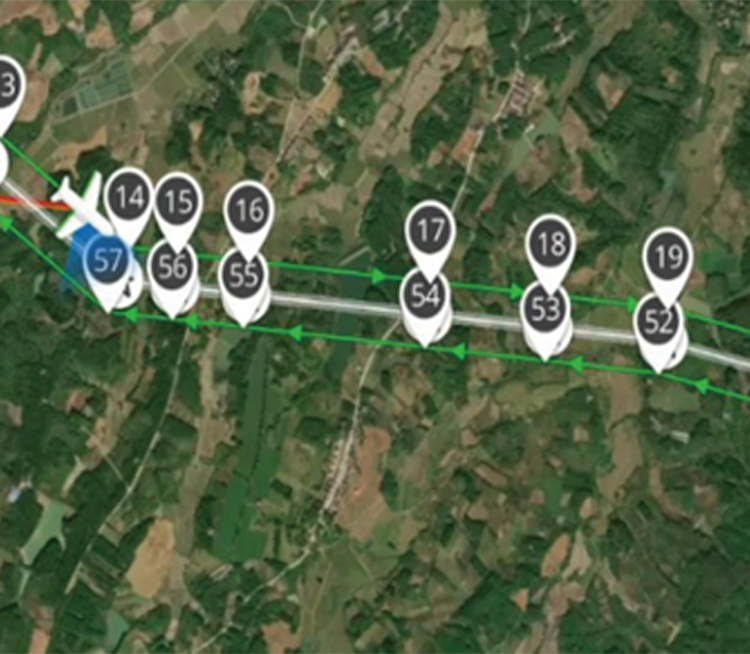

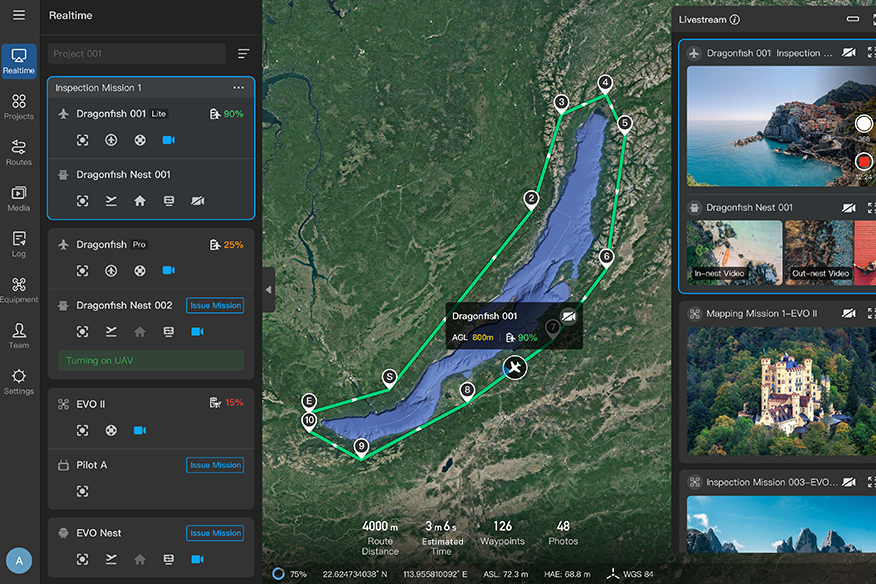

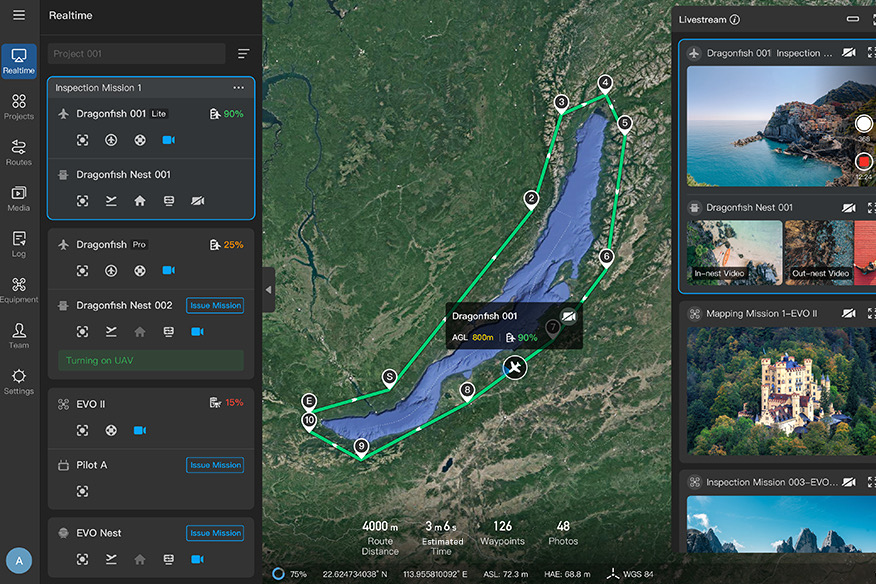

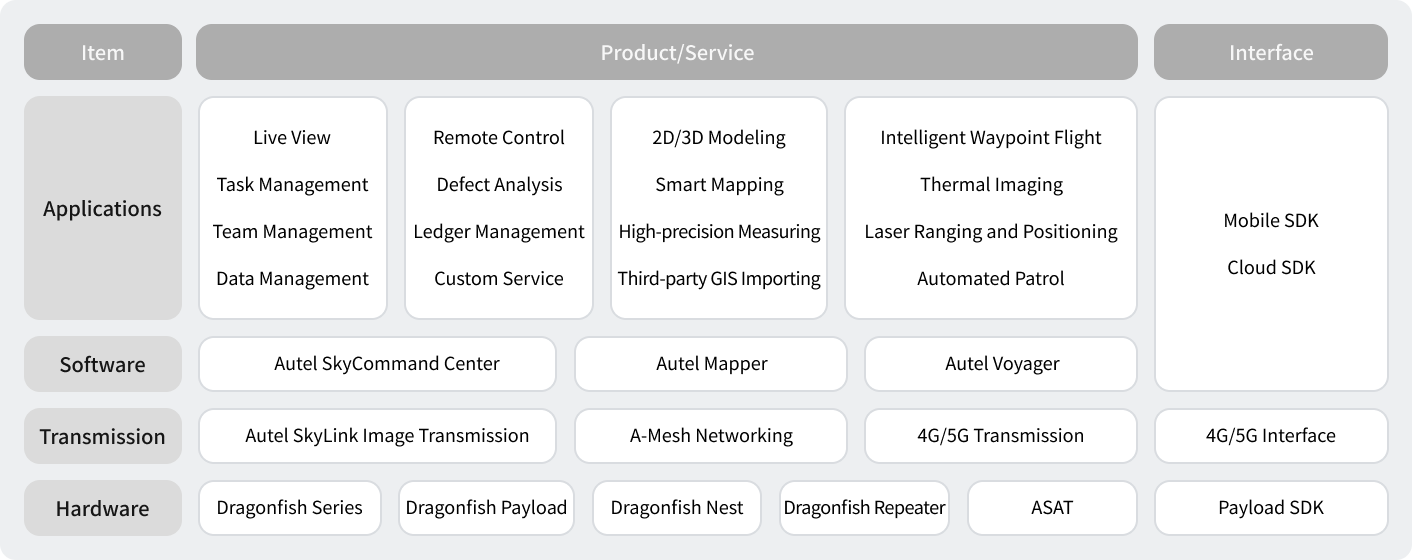

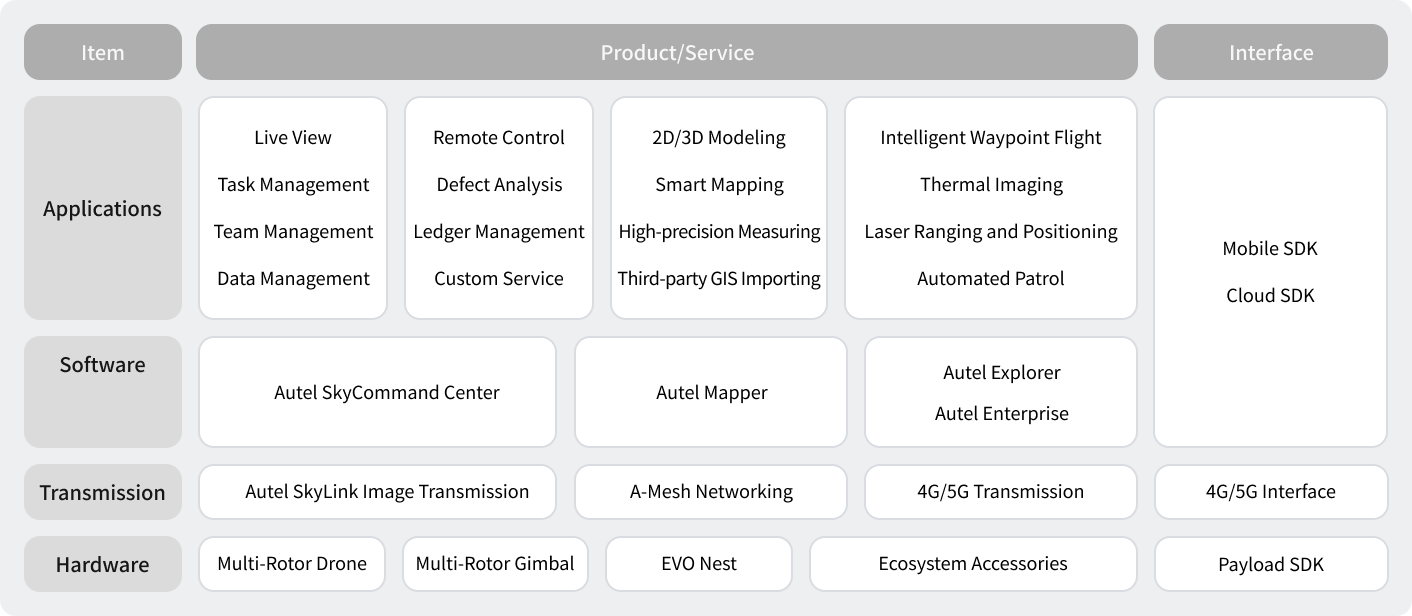

Support remote real-time import of transmission channel kml files through the remote control or Autel SkyCommand Center, and use the set of route reference points to quickly generate route planning.

Based on the self-developed Autonomy technology, the flight platform can realize autonomous flight along the route, without manual setting of 3D waypoint planning; the flight time with load is up to 158min, the flight speed is up to 108km/h, and the longest inspection of a single sortie is 60km, and it can fly at night, in rain and snow Stable operation under adverse natural conditions such as fog and haze.

Equipped with Dragonfish Nests, Autel UAV lead the industry by being completely remotely operated, and autonomous inspection can be realized without professional pilots. By installing Autel repeaters, there is no fear of signal blocking by mountains a smooth, real-time control of an operation.

After an inspection is completed, the AutelSkyCommand Center will automatically generate a complete inspection report, including inspection time, inspection line double number, route coverage section, listing abnormal intervals, abnormal descriptions and corresponding images, and assist in judging the status of lines.

158 Mins Flight Time | 3 Mins Quick Assembly

4K 50x Optical Zoom | 18.6 Miles Transmission Range

Learn More

62 Miles Transmission Range | 70Mbps Max Transmission Rate

8.5 Hours Battery Life | Centimeter Level Positioning Capacity

Learn More

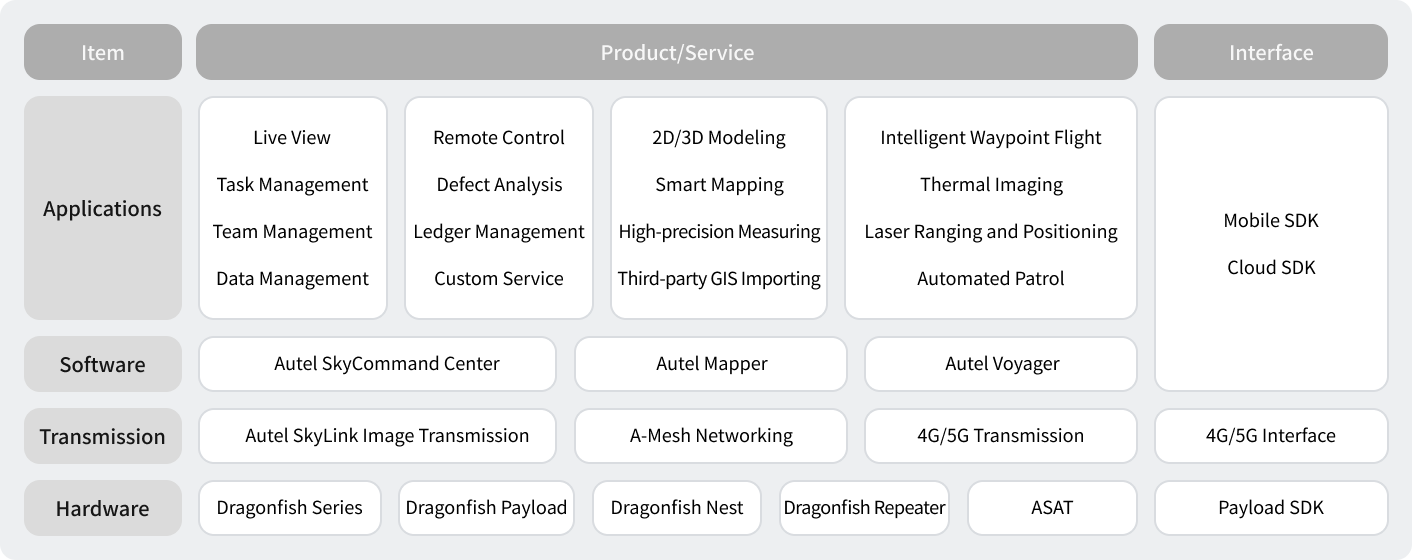

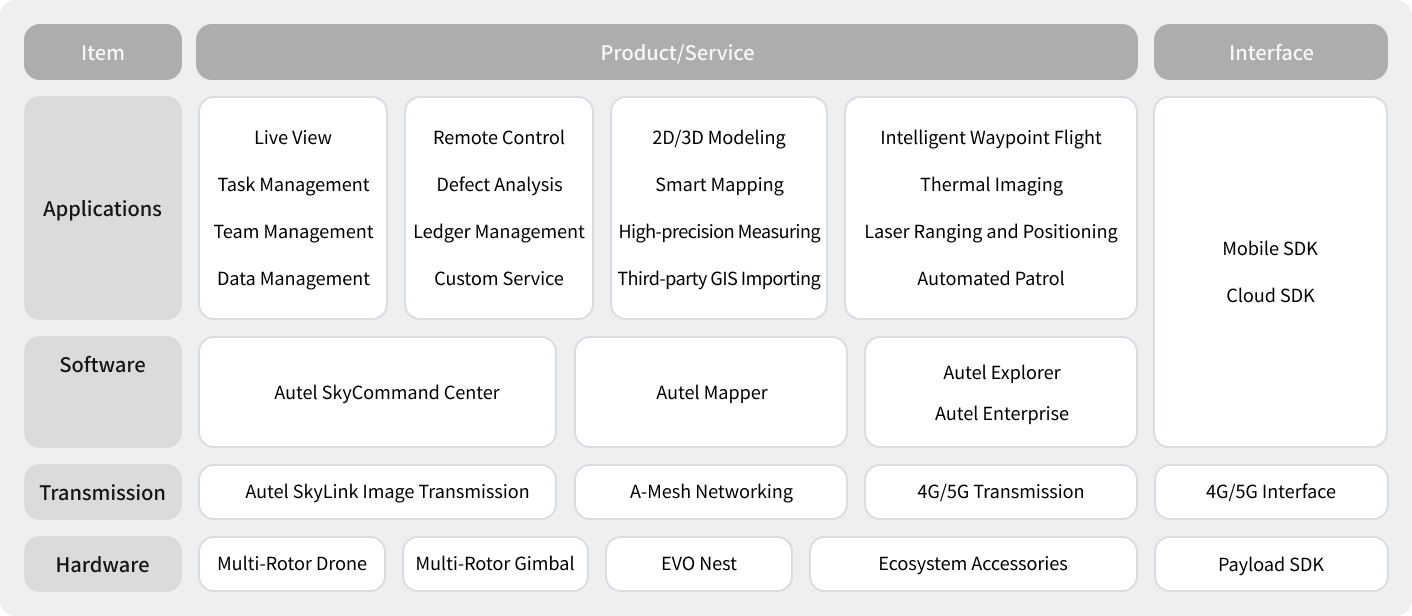

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn More

158 Mins Flight Time | 3 Mins Quick Assembly

4K 50x Optical Zoom | 18.6 Miles Transmission Range

Learn More

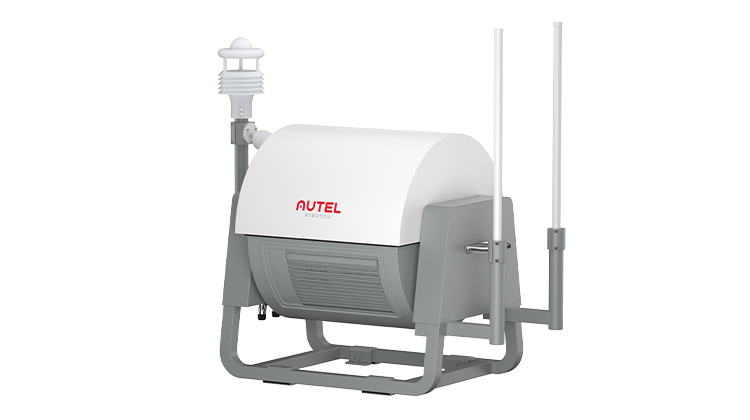

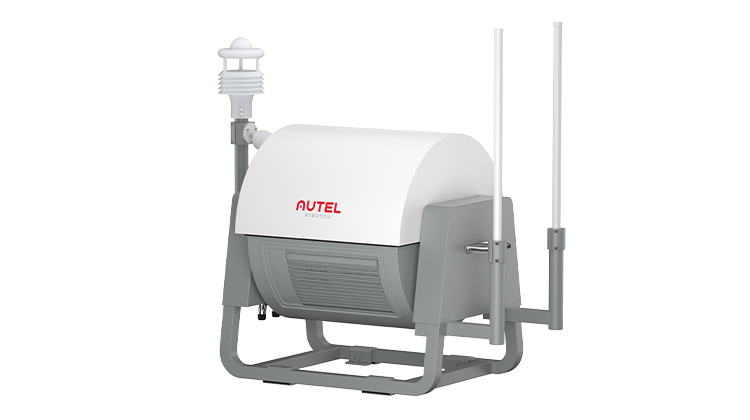

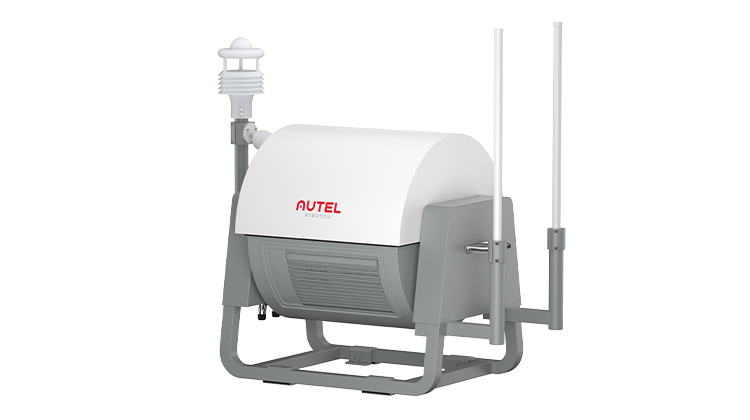

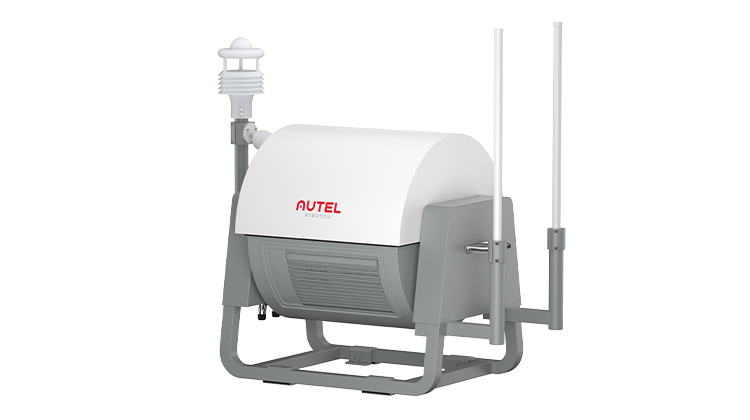

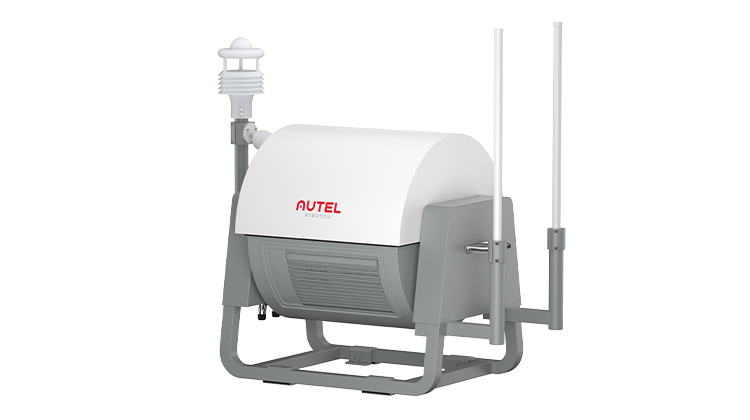

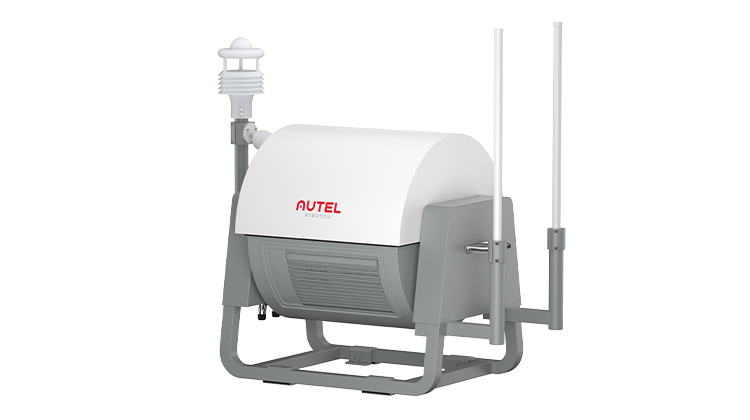

Auto Takeoff , Landing, And Charging | Weatherproof

Intelligent Data Storage And Processing | Real-time Monitor

Learn More

Self-Organizing Mesh Network | All Weather Performance

Easy Range Extending Capabilities | Real-time Monitor

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn MoreOne-click panorama, innovating data visualization, inspection and management

One-click panorama, innovating data visualization, inspection and management

Tower equipment is typically extremely complex, with a high amount of environmental factors to consider when inspecting. Multi-rotor UAV can be used to carry out detailed inspections, and the complex and changeable route trajectory is recorded through Autel's teaching algorithm, with the details of angles and time stamps memorized and saved for future use. Accurate re-shooting, importing 360° panoramas into GIS system for visual management, AI research and judgment, timely alarms and response to tower structural defects and temperature abnormalities, generating abnormal trend analysis reports, all combine to realize a multi-dimensional, independent and highly intelligent inspection routine.

Manual inspections take a long time to commute, tower climbing is inefficient and has high safety risks, and the frequency and accuracy often fail to meet quality standards of inspections.

The environment around the tower equipment is complex, with many obstacles, insufficient light, and strong signal interference.

The same point data does not have the ability to repeat the comparison of information collected each time, and there is a problem of repeated or missing shots, which cannot be processed uniformly through GIS information.

Lack of systematic and visual management models and tools, and high labor processing costs.

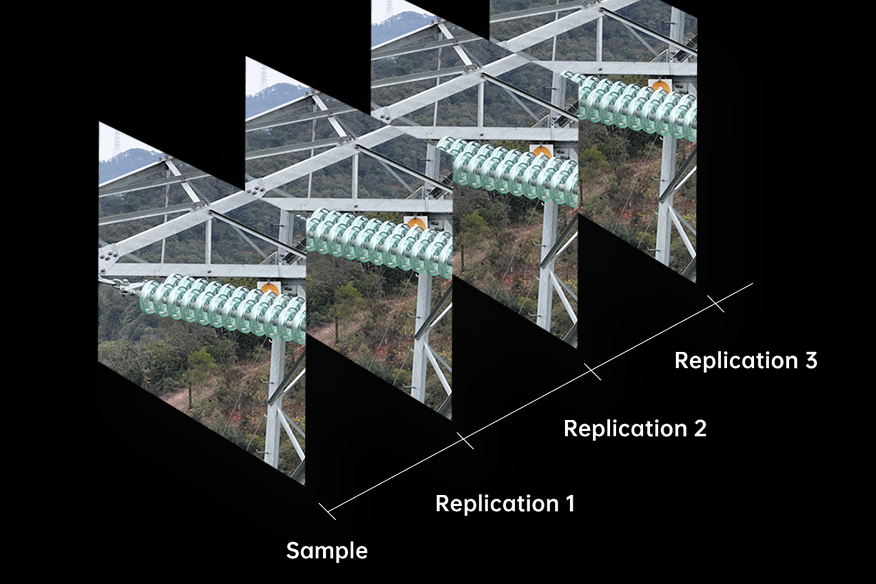

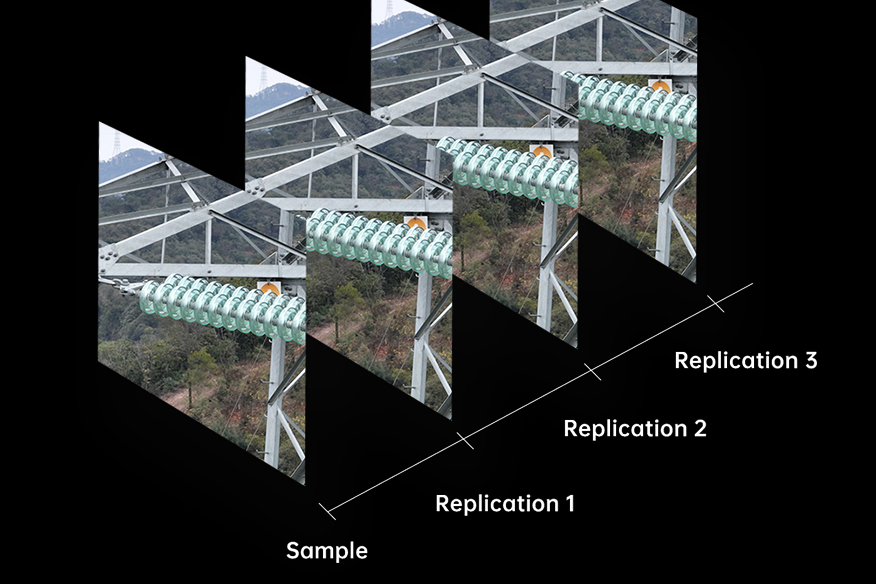

Record the flight trajectory of the UAV through a teaching method to generate a three-dimensional route, realize autonomous inspection by one-key flight, record once, and reuse for a long time, effectively solving the problem of route data acquisition in a complex environment without models.

The on-board RTK module realizes centimeter-level flight deviation correction, and AI support can automatically correct the shooting angle of the gimbal, ensuring that each point is accurately re-shot at the same coordinates and angles, improving and simplifying the convergence of sample data.

Perform "One-click Panorama" shooting above the tower to obtain 360° surrounding environment samples, and then import the tower and panoramic photos into the GIS system to build a database for visual planning and management.

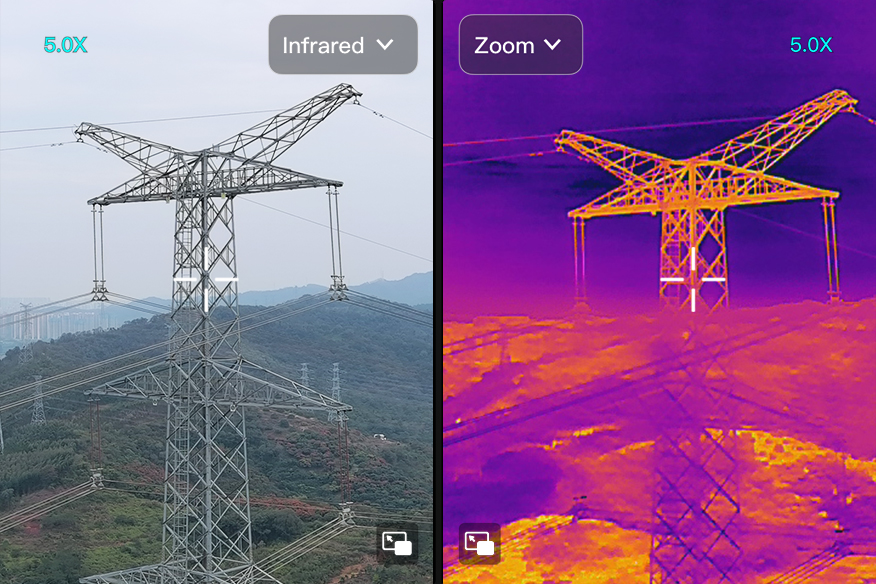

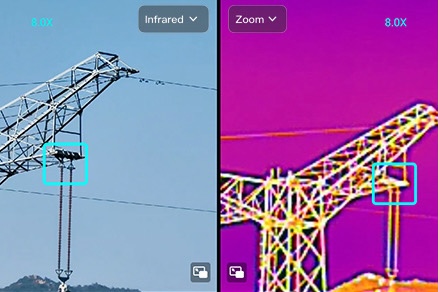

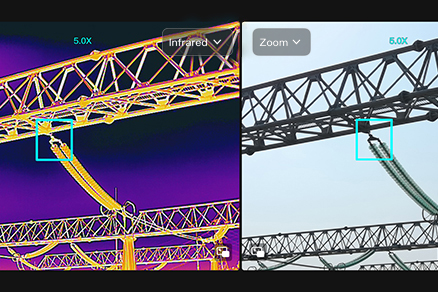

Equipped with a three-axis stabilized gimbal, equipped with a high-definition visible light + 640x512 pixel thermal imaging dual-light lens, the image is sent back to the Autel SkyCommand Center, with AI quickly able to identify structural defects and temperature abnormalities of a tower.

After an inspection is completed, Autel SkyCommand Center will automatically generate a complete inspection report, including the inspection time, the list of towers covered by the route, the list of abnormal towers, abnormal descriptions and corresponding images, and the number of abnormal towers and abnormal trend analysis by cycle.

Centimeter-Level & High-Precision Positioning System

No GCP Required | 640*512 Thermal Camera

Learn More

Autonomous, Semi-Autonomous, Or Remote Piloting | Multi-Nest Systems

All Weather Performance | Transportable & Easy Setup

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn More

720° Obstacle Avoidance | Non-GPS Return-to-Home

42 Mins Flight Time | Automatic Obstacle Rerouting

Learn More

PinPoint | Team Work | Polygon Mission

Waypoint Mission | Oblique Photography

Learn More

Autonomous, Semi-Autonomous, Or Remote Piloting | Multi-Nest Systems

All Weather Performance | Transportable & Easy Setup

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn MoreAI situational awareness drives an intelligent transformation of power substations

AI situational awareness drives an intelligent transformation of power substations

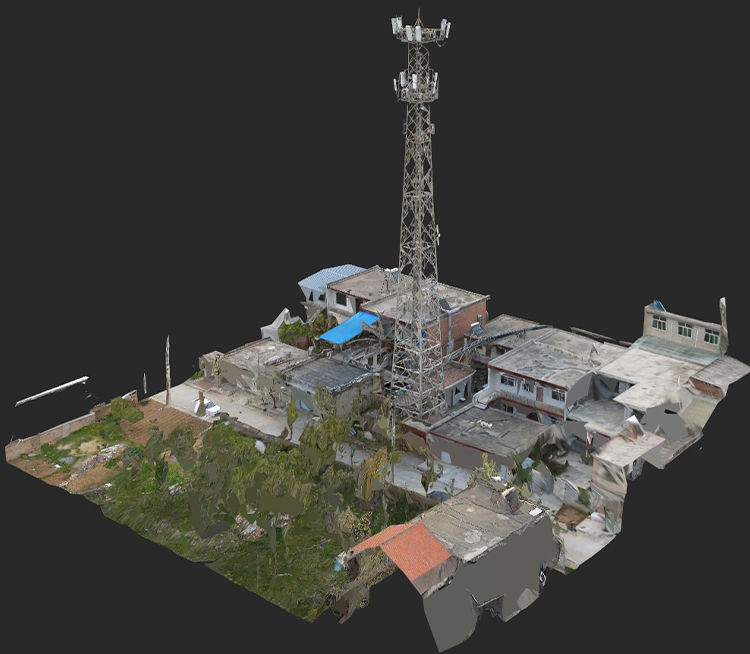

Considering high equipment density, complex spatial arrangements, and many possible faulty modules in any substation, multi-rotor UAVs can be used to construct a 2D map and 3D model of a substation with high precision, and the omnidirectional obstacle avoidance technology is applied to conduct refined 3D exploration, quickly identifying and locating faults. Through realizing three-dimensional inspections, unmanned substations can deploy Autel nests, remotely dispatching and completing tasks through the SkyCommand Center, and performing real-time detection and situation awareness to identify and solve problems before they become larger. Easily view equipment appearance, oil level, and temperature, driving an intelligent transformation of substation inspection and management, not to mention future fault research and judgement, and defect elimination tracking.

Traditional inspections are limited by distance and camera clarity, and have weak situational awareness of equipment defects, requiring a higher inspection depth.

There are many intervals in the station, high equipment density, complex spatial arrangement, and many obstacles, making it difficult for drones to fly autonomously.

Unmanned substations are usually located in remote areas, and personnel are regularly sent to the site for inspections, and commuting is time-consuming and laborious.

Existing inspections are usually marked with tables and texts, and inspection route planning and closed-loop tracking for defect elimination are not intuitive enough.

Using professional modeling software, Autel Mapper can carry out high-precision reconstruction of a 2D/3D model of a substation, performing partition display and batch management based on voltage level, geographical location, and various other operations.

Based on Autel's self-developed autonomous technology, the flying platform independently conducts 3D exploration based on omnidirectional obstacle avoidance capabilities, and can quickly discover and locate faults at various levels in the substation, realizing three-dimensional inspection.

Through Autel SkyCommand Center, inspection tasks can be issued remotely to EVO Nests, with drones able to remotely be dispatched and take off and land on their own, recharging or replacing batteries, performing flight tasks, automating and further innovating substation inspections.

Equipped with a three-axis stabilized gimbal, equipped with high-definition visible light + 640x512 pixel thermal imaging dual-light lens, the image is sent back to Autel SkyCommand Center, and AI then identifies the appearance, oil level, oil temperature, and respirator of the primary and secondary equipment in the substation, as well as general status and any abnormal issues.

After the inspection is completed, Autel SkyCommand Center will automatically generate a complete in-station inspection report, including inspection time, inspection route, covered equipment, and equipment parameter values, etc., listing abnormal equipment, descriptions, and corresponding images.

Centimeter-Level & High-Precision Positioning System

No GCP Required | 640*512 Thermal Camera

Learn More

Autonomous, Semi-Autonomous, Or Remote Piloting | Multi-Nest Systems

All Weather Performance | Transportable & Easy Setup

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn More

720° Obstacle Avoidance | Non-GPS Return-to-Home

42 Mins Flight Time | Automatic Obstacle Rerouting

Learn More

Autonomous, Semi-Autonomous, Or Remote Piloting | Multi-Nest Systems

All Weather Performance | Transportable & Easy Setup

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn MoreEyes in the distance, accelerating and supporting oil field production

Eyes in the distance, accelerating and supporting oil field production

Multi-rotor drones can carry multiple loads to carry out intelligent inspection operations on oil fields. Through a series of technologies such as visible light photography, infrared temperature measurement, and gas detection, it is possible to quickly grasp the overall operation of any station, identify and eliminate hidden dangers of leakage rapidly, and effectively improve the efficiency of oil field inspections, all while reducing labor costs, improving management level, and empowering the digitization of energy, construction and production industries.

The oil field environment is complex, pumping units are mostly distributed in canyons, high and low terrain, and there are many night patrol scenes, with unique weather, light and other problems bringing great challenges to flight.

The distribution of oil wells is irregular, and the number of oil wells can range from tens to hundreds of miles. Inspections in low-density areas have high requirements for image transmission, and the sampling results are often mixed quality.

With the improvement of the intelligence level of oil fields, more and more oil wells have adopted the unmanned mode, and the machine patrol based on manual operation cannot meet the needs of new scenarios.

Easily adaptable, able to operate in environments of -4°F to 122°F, take off, land and fly stably at a wind speed of up to 12m/s, with 40min ultra-long battery life, 15km ultra-long-distance high-definition image transmission, with proven success in canyons and undulating terrain, comfortably able to work normally at night and in bad weather, with strong anti-radio frequency interference capability.

Align orthographic images, one-click panorama, and intelligent archiving of photos for refined inspection of facilities, support multi-layer labeling, label pumping wells, self-flowing wells and other equipment, integrate AI and AR applications, and quickly carry out analysis of oil spills and well shutdowns, utilizing our digital platforms for efficient operations and maintenance.

Reasonable site selection can be made based on the terrain of an oil field, and multi-rotor aircraft nests can be deployed in a grid manner. Each aircraft nest can cover oil wells within a radius of just over 4 miles (4.3mi). The operation is uniformly dispatched through the Command Center, and on-site maintenance is free for an extended period.

At the end of the inspection, a report is intelligently generated, including inspection time, route map, exception list, photos of abnormal points, text description, etc.

9.3 Miles/15km FCC | RTK Module Compatible

ADS-B Signal Receiver | 42 Mins Flight Time

Learn More

PinPoint | Team Work | Polygon Mission

Waypoint Mission | Oblique Photography

Learn More

9.3 Miles/15km FCC | RTK Module Compatible

ADS-B Signal Receiver | 42 Mins Flight Time

Learn More

PinPoint | Team Work | Polygon Mission

Waypoint Mission | Oblique Photography

Learn More

Autonomous, Semi-Autonomous, Or Remote Piloting | Multi-Nest Systems

All Weather Performance | Transportable & Easy Setup

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn More

720° Obstacle Avoidance | Non-GPS Return-to-Home

42 Mins Flight Time | Automatic Obstacle Rerouting

Learn More

PinPoint | Team Work | Polygon Mission

Waypoint Mission | Oblique Photography

Learn More

Autonomous, Semi-Autonomous, Or Remote Piloting | Multi-Nest Systems

All Weather Performance | Transportable & Easy Setup

Learn More

Project And Mission Management | Offline Mesh Network

Multi-Channel Live Streaming | Remote Fleet Control | Data Storage And Analytic

Learn More